What is a 3 Threaded Ball Valve? Key Features and Applications Explained

The 3 threaded ball valve is a crucial component in many industrial applications, providing efficient flow control and ease of operation. This type of valve stands out due to its uniquely designed threads which facilitate quick connections and disconnections, thereby enhancing maintenance efficiency. Understanding the key features and functionalities of the 3 threaded ball valve is essential for professionals in engineering, manufacturing, and process industries, as it plays an integral role in fluid regulation and system reliability.

In this article, we will delve into the key characteristics that define the 3 threaded ball valve, including its design attributes, operational benefits, and suitability for various applications. By exploring their significance in maintaining workflow efficiency, the application domains of these valves can be better comprehended. The insights provided will serve as a valuable resource for decision-makers and engineers seeking to optimize their systems through the effective use of 3 threaded ball valves.

What is a 3 Threaded Ball Valve?

A 3 threaded ball valve is a type of valve that utilizes a hollow, perforated sphere (the ball) to control the flow of fluid through it. The unique feature of this valve design is that it is fitted with three threaded ports, allowing it to connect and redirect flow in multiple directions. This capability makes the valve particularly versatile in various piping systems, as it can efficiently manage the flow from one inlet to two outlets or vice versa, depending on the operational requirements.

The construction of a 3 threaded ball valve typically includes durable materials that can withstand various pressures and temperatures, which is essential for both industrial and residential applications. Its ability to provide a reliable seal when closed, alongside minimal flow resistance when open, ensures that the valve operates efficiently. This type of valve is widely used in industries such as water treatment, oil and gas, and HVAC systems, where precise flow control and easy switching between different flow paths are necessary.

3 Threaded Ball Valve Applications and Usage

Understanding the Design and Structure of 3 Threaded Ball Valves

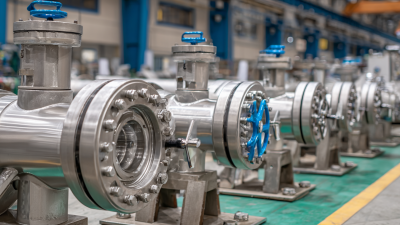

A 3 threaded ball valve is a pivotal component in various industrial applications due to its unique design and structural features. Unlike standard ball valves, the 3 threaded variant allows for the connection of three pipes, enhancing the versatility of flow control within a system. The design typically consists of a spherical disc (the ball) with three threaded ports, which can significantly minimize pressure drops across piping systems. According to a report by Research and Markets, the global valve market, including ball valves, was valued at approximately $66.5 billion in 2022, and is projected to reach $87.6 billion by 2027, illustrating a strong demand for sophisticated valve technologies.

From a structural perspective, a 3 threaded ball valve can be crafted from various materials including stainless steel, brass, and plastic, which contributes to its adaptability across different environments. The valve features thread patterns that accommodate easy installation and maintenance, reducing downtime during operational phases. Technical studies indicate that this type of valve can operate efficiently in high-pressure conditions, with a recommended pressure rating ranging from 150 to 300 psi, making it suitable for use in industries such as oil and gas, water treatment, and food processing. Its ability to effectively manage flow direction and shut off fluid flow makes it an invaluable asset in any industrial setup.

Key Features and Benefits of Using a 3 Threaded Ball Valve

A 3 threaded ball valve is a versatile and efficient option for controlling fluid flow in various industrial applications. One of the key features of this type of valve is its ability to perform three-way flow control, allowing it to direct flow between two different lines or redirect the flow of a single line. This makes it an ideal choice for mixing or diverting media, providing high flexibility in process control.

The benefits of using a 3 threaded ball valve include ease of operation, low torque requirements, and minimal pressure drop across the valve when open. These valves typically feature a tight seal to prevent leaks, enhancing safety and efficiency in fluid handling systems. Additionally, their compact design allows for installation in tight spaces without sacrificing performance.

Tips: When selecting a 3 threaded ball valve, consider the materials of construction to ensure compatibility with the fluids being handled. Regular maintenance, such as checking the seals and actuators, can help prolong the lifespan and reliability of the valve, ensuring optimal performance in your applications.

Common Applications for 3 Threaded Ball Valves in Various Industries

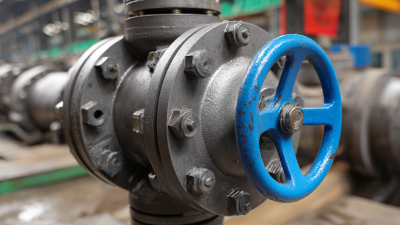

3 threaded ball valves are widely used across various industries due to their unique design and functionality. These valves are particularly effective in applications that require tight sealing and reliable flow control. In the oil and gas industry, for example, 3 threaded ball valves are crucial for managing the flow of hydrocarbons under high pressure. Their ability to quickly open and close with a quarter-turn operation makes them ideal for emergency shut-off applications, ensuring the safety and integrity of the system.

In the manufacturing sector, 3 threaded ball valves are often used in hydraulic systems to regulate fluid flow. Their robust construction and resistance to wear make them suitable for handling aggressive fluids in chemical processing plants. Additionally, in water treatment facilities, these valves help in the precise control of water flow, contributing to the efficient management of resources. By providing reliable performance across these varied applications, 3 threaded ball valves play a critical role in enhancing operational efficiency and safety in multiple industrial contexts.

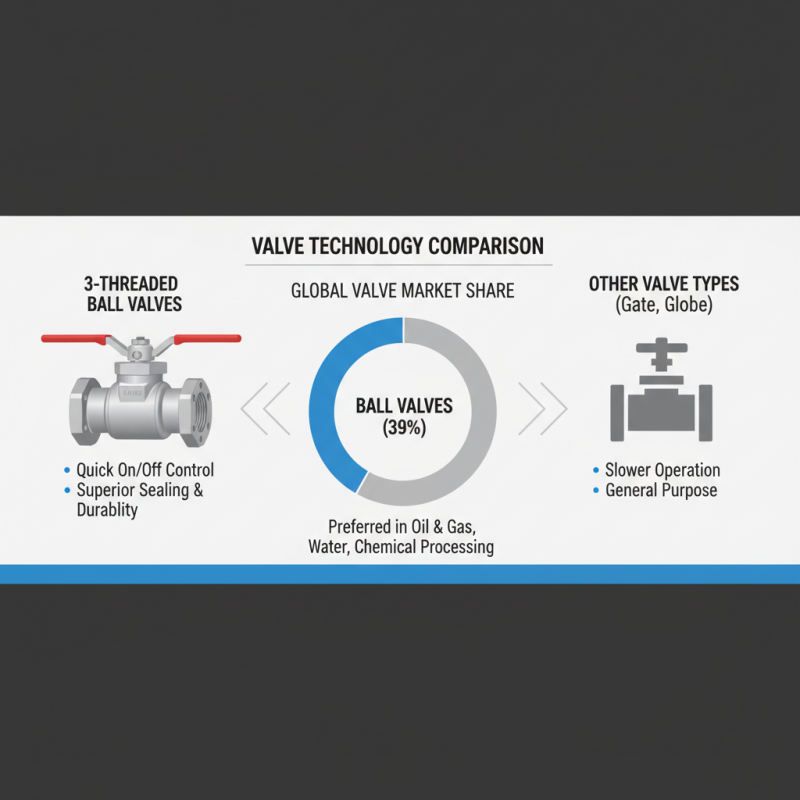

Comparing 3 Threaded Ball Valves with Other Valve Types

When comparing 3 threaded ball valves to other valve types, the focus shifts to their unique functionalities and applications. The 3 threaded ball valve, known for its reliable sealing capabilities and ease of operation, typically outperforms traditional gate and globe valves in scenarios requiring quick on-off controls. A comprehensive report from the Global Valve Market Research indicates that ball valves account for approximately 39% of the valve market share, thanks to their versatility and durability, making them a preferred choice in various industries, including oil and gas, water supply, and chemical processing.

In contrast to other valve types, such as butterfly valves, which can be less effective under high pressure, 3 threaded ball valves provide a robust solution, ensuring minimal pressure drop. Their design also facilitates smoother flow, which is essential for applications where fluid dynamics are critical. According to industry analyses, sectors that demand high performance, like petrochemical, project a steady advancement in the adoption of ball valves, with expected growth rates of over 5% in the coming years.

Tip: When selecting a valve for your system, consider not only the application but also the maintenance requirements and lifespan of the valve type. Ensuring compatibility with existing piping and fluid characteristics can significantly enhance operational efficiency. Additionally, consulting industry standards can provide insights that benefit both short-term functionality and long-term reliability.

Related Posts

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

7 Unique Benefits of Metal Seated Ball Valves for Global Procurement Success

-

Exploring the Best Ball Valve Ball Options for 2025 Top Industry Standards

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data