What is a Ball Valve Ball and How to Choose the Right One

In the realm of fluid control systems, the ball valve ball stands out as a critical component that ensures optimal performance and reliability. Experts in the industry, such as John Smith, a renowned valve specialist, emphasize the importance of choosing the right ball valve ball for specific applications. He famously stated, “The efficiency of a ball valve hinges on the precise selection of its ball; this choice can significantly impact flow control and system durability.”

Choosing the appropriate ball valve ball is not merely a matter of preference but an essential decision that can affect the overall efficiency and longevity of the system. With various materials, sizes, and configurations available, understanding the intricacies of ball valve balls becomes imperative for engineers and procurement specialists alike.

As we delve deeper into the aspects that define the ideal ball valve ball, we will explore factors such as material compatibility, pressure ratings, and installation considerations. By aligning the characteristics of the ball valve ball with the specific operational requirements, one can enhance performance and ensure a robust flow control solution.

Understanding the Functionality of a Ball Valve Ball

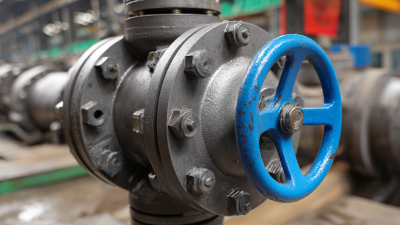

A ball valve ball is a critical component in a ball valve, which functions as a flow control device in various industrial applications. The ball, usually made of durable materials like stainless steel, plastic, or brass, rotates on a fixed axis to either open or close the valve, allowing or restricting the flow of fluids. According to a 2022 report by the Global Market Insights Inc., the ball valve market is expected to surpass $12 billion by 2026, driven by their efficiency and reliability in diverse industries such as oil and gas, water treatment, and pharmaceuticals.

When choosing the right ball valve ball, it’s essential to consider factors such as material compatibility, pressure ratings, and temperature limits. For instance, a study from the American Society of Mechanical Engineers (ASME) highlights that incorrect material selection can lead to premature failure or leakage, emphasizing the need to match the ball with the operational environment. Additionally, understanding the dimensions and design standards, such as those from the American National Standards Institute (ANSI), ensures that the selected ball will fit seamlessly within the valve assembly, providing optimal performance and longevity.

What is a Ball Valve Ball and How to Choose the Right One

| Dimension | Material | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|---|

| 1/4 inch | Brass | 600 psi | -20 to 150 °F | Water, Oil |

| 1/2 inch | Stainless Steel | 1000 psi | -50 to 300 °F | Chemical Processing |

| 3/4 inch | PVC | 150 psi | -10 to 140 °F | Irrigation, Pool Systems |

| 1 inch | Carbon Steel | 1500 psi | -29 to 400 °F | Oil and Gas |

| 2 inch | Ductile Iron | 250 psi | -20 to 150 °F | Water Supply, Fire Protection |

Types of Ball Valve Balls and Their Applications

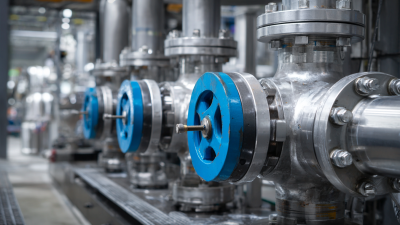

Choosing the right ball valve ball is crucial for ensuring optimal performance in various applications. Ball valve balls are typically made from materials such as stainless steel, brass, and plastics, each offering unique advantages. According to a report by MarketsandMarkets, the global ball valve market is projected to reach $9.5 billion by 2026, driven by the increasing demand in industries such as oil and gas, water treatment, and chemical processing.

There are several types of ball valve balls utilized in different industries: floating balls, trunnion-mounted balls, and high-performance balls. Floating balls are commonly used in low-pressure systems and are versatile due to their ability to seal effectively with less force. Trunnion-mounted balls, typically used in larger valves, offer enhanced stability and lower operating torque, making them ideal for high-pressure applications. High-performance balls, manufactured from advanced materials like carbon composites, are increasingly popular in aggressive environments, providing durability and resistance to wear. According to a 2022 study from the American Society of Mechanical Engineers, using the appropriate type of ball valve ball can reduce leakage rates by up to 30%, significantly impacting efficiency and safety.

Types of Ball Valve Balls and Their Applications

Key Factors to Consider When Choosing a Ball Valve Ball

When selecting a ball valve ball, several key factors must be considered to ensure optimal performance and longevity. Firstly, the material of the ball is pivotal. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), materials such as stainless steel, PVC, and brass are preferred for their durability and corrosion resistance. For high-pressure applications, stainless steel is often the best choice, providing excellent strength and resistance to extreme temperatures.

Another critical consideration is the size and compatibility of the ball valve ball with the existing system. A mismatch can lead to inefficiencies and system failures. The American Society of Mechanical Engineers (ASME) suggests that the flow rate and pressure specifications should guide the selection process. Additionally, understanding the application environment—such as whether the valve will be used in a clean water system or a chemical processing plant—can significantly affect the choice of materials and ball design. Adhering to these factors not only enhances the reliability of the valve but also contributes to the overall efficiency of the fluid control system.

Material Options for Ball Valve Balls: Pros and Cons

When selecting a ball valve ball, material choice plays a critical role in performance and durability. Common materials include

stainless steel, brass, plastic, and ceramic,

each offering distinct advantages and disadvantages.

Stainless steel is renowned for its strength and resistance to corrosion, making it suitable for high-pressure and high-temperature applications. However, it can be

more expensive than other options. Brass provides a good balance of strength and cost but may not perform well in highly corrosive environments.

Plastic balls offer lightweight solutions with excellent chemical resistance, making them ideal for specific applications like water treatment.

Nevertheless, they might not withstand high pressures or temperatures. Ceramic balls are incredibly durable and wear-resistant, but their

brittleness can lead to fractures under certain conditions.

Tips: When choosing the right material for your ball valve ball, consider the working environment.

Assess factors like temperature, pressure, and the type of fluids being handled.

It's also wise to consult with manufacturers to ensure compatibility with your specific application requirements.

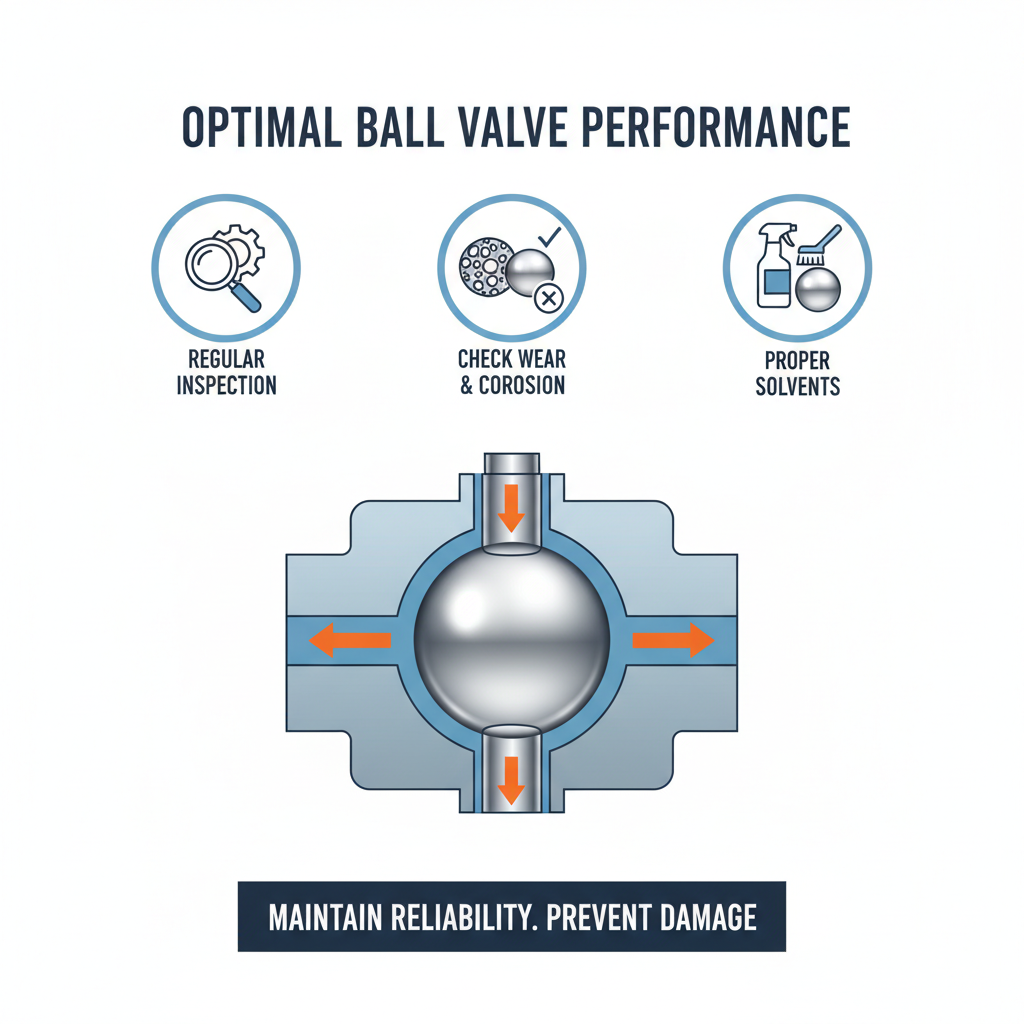

Maintenance Tips for Ensuring Longevity of Ball Valve Balls

Maintaining the longevity of ball valve balls is crucial for ensuring optimal performance and reliability within various industrial applications. Regular inspection should be a cornerstone of any maintenance routine. You should check for signs of wear, corrosion, and buildup of debris, which can hinder the valve's functionality. Cleaning mechanisms should involve suitable solvents for the materials used, ensuring that aggressive chemicals do not damage the ball’s surface.

Lubrication plays a vital role in maintaining the ball valve ball's integrity. Selecting the correct lubricant can reduce friction and wear, thus extending the lifespan of the valve. Ensure the lubricant is compatible with both the operating environment and the materials of the ball and seat. Additionally, proper torque settings during reassembly after maintenance tasks are essential to prevent leaks and ensure that the valve operates smoothly. Implementing a preventive maintenance schedule can significantly reduce unexpected failures and downtime, ensuring that the ball valve remains in top condition.

Related Posts

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications

-

Exploring the Best Ball Valve Ball Options for 2025 Top Industry Standards

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications