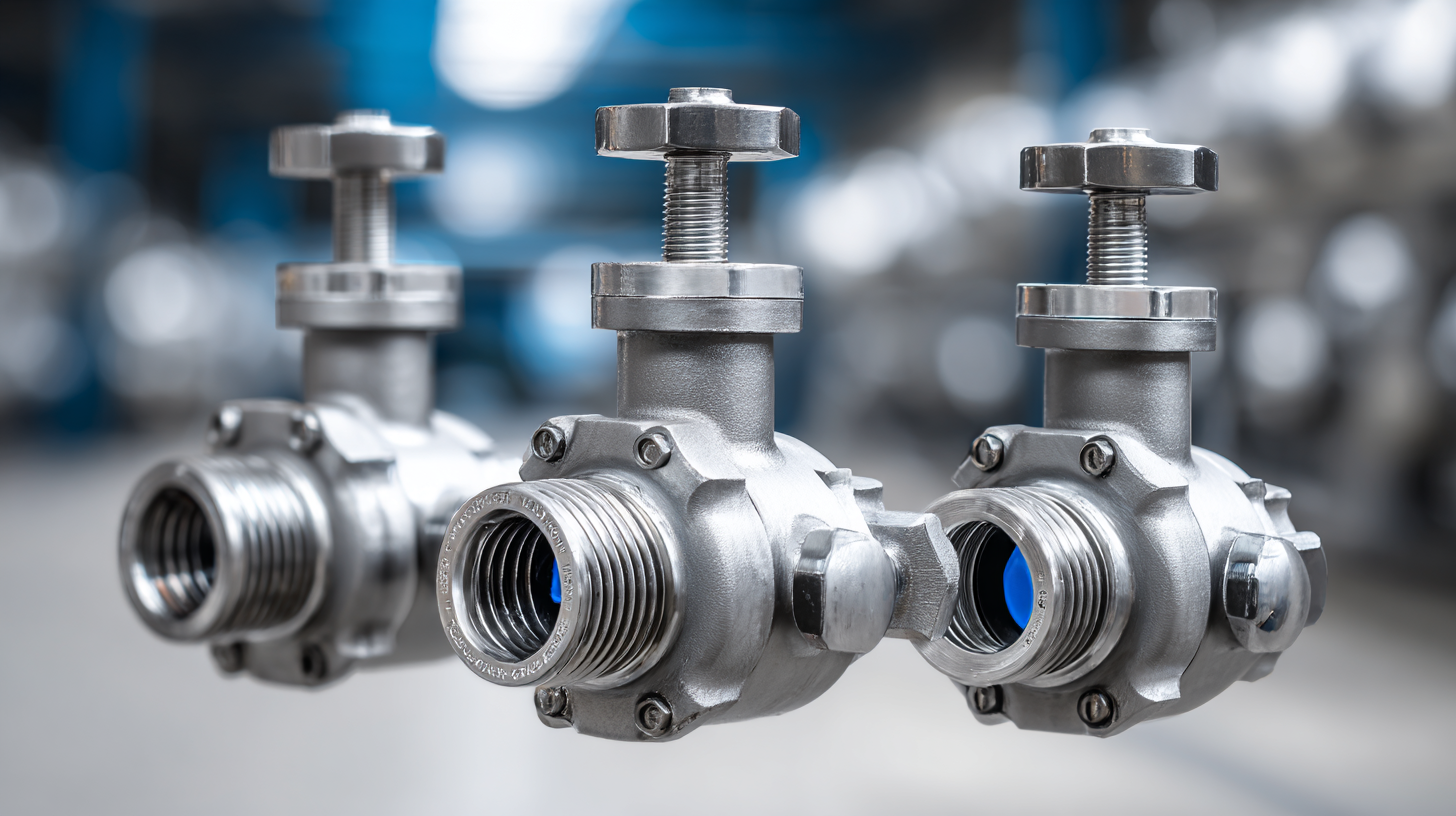

Global Leaders Choice for Best Three Way Ball Valves Quality Manufacturing from China

In the rapidly evolving global market, sourcing high-quality components is crucial for manufacturers and industrial operators. The three way ball valve, a vital component in various fluid control systems, has seen a significant surge in demand, with the global market projected to reach USD 16 billion by 2026, growing at a CAGR of 5.1% from 2021 to 2026, according to a recent industry report by Markets and Markets. As the demand escalates, especially for precision-engineered products, many businesses turn to China for cost-effective solutions. However, finding a reliable supplier in this vast landscape can be a daunting task. This blog will guide you through essential strategies and a checklist to identify high-quality manufacturers of three way ball valves in China, ensuring that your sourcing process yields exceptional outcomes while meeting industry standards and specifications.

Trends in Three Way Ball Valve Manufacturing: A 2025 Market Overview

As we approach 2025, the manufacturing landscape for three-way ball valves is undergoing significant transformations driven by advancements in technology and increasing global demand. Manufacturers in China are leveraging innovative techniques, such as automation and precision machining, to enhance production efficiency and product quality. This shift not only ensures that these valves meet stringent international standards but also positions Chinese manufacturers as frontrunners in the global market.

Moreover, sustainability is becoming a crucial trend in the three-way ball valve sector. Companies are integrating eco-friendly materials and manufacturing processes that minimize waste and reduce energy consumption. This commitment to green manufacturing not only appeals to environmentally conscious consumers but also aligns with global initiatives aimed at carbon footprint reduction. As the industry evolves, we can expect to see a greater emphasis on creating durable, high-performance valves that cater to the diverse needs of various sectors, from oil and gas to water treatment.

Key Quality Standards for Chinese Manufactured Ball Valves

In the fast-evolving world of industrial valves, the quality of manufacturing is paramount, especially when it comes to three-way ball valves sourced from China. Chinese manufacturers have gained a reputation for producing high-quality ball valves that meet rigorous global standards. These valves are integral to various sectors, including oil and gas, chemical processing, and water treatment, making quality assurance essential both for performance and safety.

To ensure that their products meet the key quality standards, Chinese manufacturers often adhere to international certifications such as ISO 9001, which outlines quality management principles. Furthermore, compliance with industry-specific standards, such as API and ASME, underscores the manufacturers' commitment to excellence. Rigorous testing procedures, including pressure and leakage testing, are also implemented to validate the performance and durability of the valves before they reach the market. As a result, customers can trust that these three-way ball valves not only meet but often exceed expectations in quality and reliability.

How to Choose the Right Three Way Ball Valve for Your Industry Needs

When selecting the right three-way ball valve for your industry's specific needs, it's essential to consider several key factors such as flow direction, pressure ratings, and materials of construction. According to a recent report by Grand View Research, the global ball valve market is projected to reach $11.93 billion by 2025, highlighting the increasing demand across various sectors, including oil and gas, chemicals, and water treatment.

One of the critical aspects to evaluate is the valve's design—whether it's L-port or T-port—since this directly influences flow capacity and directional control. For instance, L-port valves allow for flow in two directions but cannot mix efficiently, while T-port valves offer the versatility of mixing flows. Additionally, material selection plays a vital role; materials such as stainless steel or cryogenic materials can significantly impact performance under different temperature and pressure conditions. According to a report from MarketsandMarkets, advancements in valve technologies and materials are expected to drive market growth, making it crucial for industries to choose the right product to ensure optimal performance and reliability in their operations.

Insights from Global Leaders on Ball Valve Supplier Selection

In the increasingly competitive landscape of manufacturing, the selection of reliable ball valve suppliers has become a focal point for global leaders. This decision is particularly crucial in industries requiring high-quality components, where even minor imperfections can lead to significant operational failures.

Insights gathered from industry experts reveal that suppliers known for their stringent quality control processes, innovative technology, and robust customer support often stand out in the selection process. Global leaders emphasize the importance of supplier reputation, which is often built on proven performance and reliability over time. Additionally, the ability to meet international standards and provide customized solutions based on specific project needs is a significant advantage.

As industries continue to evolve, empowering advanced manufacturing techniques such as automation and smart technologies will likely further shape the dynamics of supplier selection in the ball valve sector. These criteria not only enhance operational efficiency but also drive long-term partnerships that benefit all stakeholders involved.

Future Innovations in Ball Valve Technology: What to Expect by 2025

As we look towards 2025, the landscape of ball valve technology is poised for exciting advancements that promise to enhance performance and efficiency in various industries. One of the most anticipated innovations is the integration of smart technology into ball valves. This development will allow for real-time monitoring and data collection, enabling operators to optimize performance and predict maintenance needs, ultimately reducing downtime and costs.

Another significant trend is the growing emphasis on sustainability in manufacturing processes. Leading manufacturers are investing in eco-friendly materials and techniques, which not only minimize environmental impact but also enhance product durability. As a result, the next generation of ball valves will not only meet stringent regulatory standards but also cater to the increasing demand for green solutions from industries such as oil and gas, water treatment, and power generation. These innovations will not only drive the efficiency of ball valves but will also align with global initiatives aimed at reducing carbon footprints.

Global Leaders Choice for Best Three Way Ball Valves Quality Manufacturing from China - Future Innovations in Ball Valve Technology: What to Expect by 2025

| Feature | 2023 Status | Expected Innovations by 2025 |

|---|---|---|

| Material Quality | High-grade stainless steel | Advanced composites for corrosion resistance |

| Production Techniques | Traditional machining and assembly | 3D printing and automation in production |

| Control Mechanism | Manual and pneumatic controls | Smart control systems with IoT integration |

| Energy Efficiency | Moderate energy consumption | Increased efficiency through optimization technologies |

| Market Demand | Steady growth | Projected surge due to new industrial applications |