What is a Brass Valve? Types, Uses, and Benefits Explained

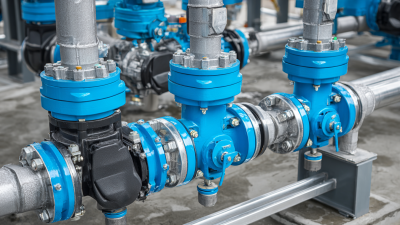

Brass valves are essential components in various plumbing and industrial applications, known for their durability and resistance to corrosion. These valves are made from a copper-zinc alloy, providing a balance of strength and malleability, which makes them suitable for a wide range of uses, from controlling water flow in residential plumbing to regulating gas in industrial settings. Their versatility and reliability have led to their widespread adoption across multiple sectors.

This article delves into the different types of brass valves available, highlighting their unique features and functions. It explores how these valves are employed in various systems, including water supply, heating, and gas distribution, emphasizing the benefits they bring to both residential and commercial setups. Understanding the characteristics and applications of brass valves not only helps in selecting the right components for specific needs but also underscores their significant role in ensuring efficient and safe operations across numerous industries.

Definition and Functionality of Brass Valves

Brass valves are essential components in various plumbing and industrial applications, devised primarily for controlling the flow of liquids and gases. Made from an alloy of copper and zinc, brass offers excellent durability, corrosion resistance, and ease of machinability, which makes it a popular choice for valve construction. The functionality of a brass valve hinges on its ability to open, close, or partially obstruct pathways, allowing users to regulate flow rates effectively. These valves can be manually operated or automated, catering to a wide range of operational requirements.

In terms of types, brass valves come in various forms, including globe valves, ball valves, check valves, and gate valves, each designed for specific applications and flow control needs. Globe valves, for example, are used primarily for throttling flow, while ball valves are ideal for quick on/off control. The versatility and reliability of brass valves allow them to function in diverse environments, from residential plumbing systems to large industrial processes. The combination of strength and resistance to wear makes brass valves not only efficient but also a cost-effective solution for managing fluid movement in various systems.

Common Types of Brass Valves and Their Applications

Brass valves are essential components in various plumbing and industrial applications, known for their durability and resistance to corrosion. Among the different types of brass valves, the most common include gate valves, globe valves, ball valves, and check valves, each serving specific functions in fluid regulation and control. Gate valves, for instance, are primarily used for on/off control as they provide minimal flow restriction when fully open, making them ideal for pipelines that require a straight flow path.

On the other hand, globe valves are designed to regulate the flow of liquids and gases more efficiently due to their shape, which allows for better throttling capabilities. Ball valves are prized for their quick shut-off capabilities and are often found in applications where a tight seal is necessary. Lastly, check valves prevent backflow in systems, thus protecting equipment from potential damage. Each type of brass valve offers unique advantages tailored to specific applications, from residential plumbing to industrial uses, ensuring reliable performance in fluid management systems.

Brass Valve Types and Their Applications

Benefits of Using Brass Valves in Various Industries

Brass valves are commonly used in various industrial applications due to their excellent corrosion resistance and durability. One of the significant benefits of using brass valves is their ability to withstand high pressures and temperatures, making them ideal for environments such as piping systems in water treatment plants and chemical processing facilities. According to a report by the Global Brass and Copper Alloy Market, the demand for brass products, including valves, is projected to grow at a CAGR of 4.8% from 2021 to 2026, indicating their increasing utilization across industries.

Moreover, the versatility of brass valves enables them to perform effectively in both HVAC systems and plumbing installations. Their superior sealing properties minimize leakage risks, enhancing system efficiency and reducing overall maintenance costs. A study by the American Society of Mechanical Engineers (ASME) highlights that using brass valves can lead to energy savings of up to 20% in large-scale manufacturing operations due to decreased pressure losses and optimized flow rates. This benefit is particularly advantageous for industries focused on sustainability and cost reduction, as it helps in maintaining compliance with environmental regulations while improving operational performance.

In the context of the food and beverage industry, brass valves are often selected for their sanitary properties. The FDA recognizes brass components for their reliability; this is crucial in applications where hygiene is paramount. By incorporating brass valves, food processing companies can ensure that their operations maintain the highest sanitary standards, further reinforcing the material's essential role across various sectors.

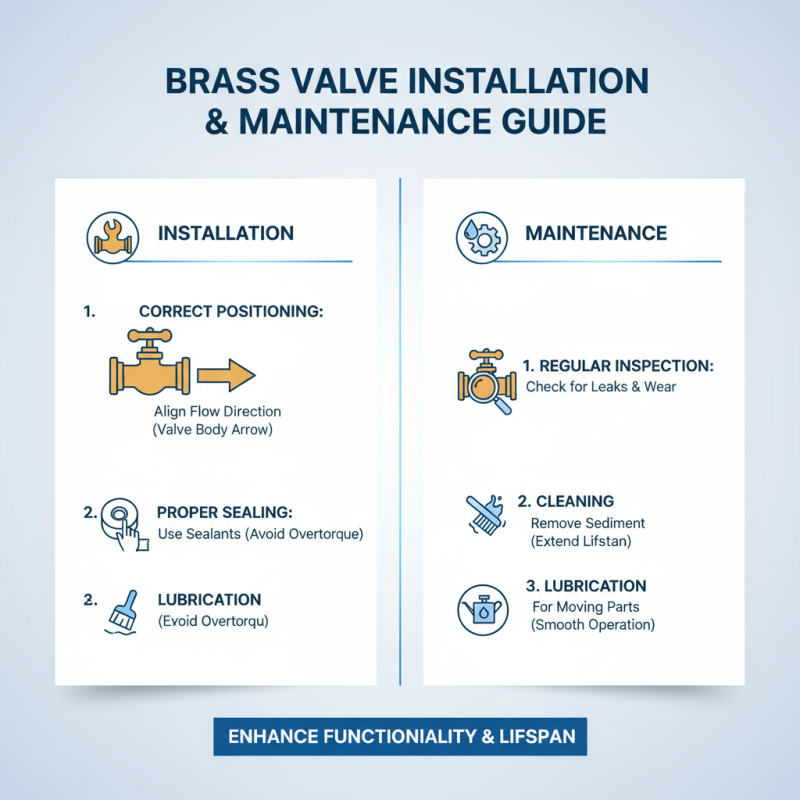

Installation and Maintenance Tips for Brass Valves

When considering the installation and maintenance of brass valves, proper procedures can significantly enhance their functionality and lifespan. Firstly, during installation, ensure that the valve is positioned correctly within the pipeline. The direction of flow should always align with the arrows marked on the valve body. This simple step can prevent reverse flow issues and ensure optimal performance. Additionally, use appropriate sealing materials to prevent leaks, as brass valves can be sensitive to excessive torque when tightening fittings.

Maintenance plays a crucial role in the longevity of brass valves. Regular inspection is essential; check for any signs of corrosion or wear, especially in areas with high moisture. Clean the valve periodically with a soft cloth to remove any buildup from external elements. Furthermore, lubricating the valve's moving parts can help maintain smooth operation and prevent seizing. This simple tip can dramatically improve the ease of valve operation and prolong its service life.

Lastly, make it a habit to test the valve periodically under operating conditions to ensure it is functioning correctly. Catching minor issues early can prevent costly repairs in the future and ensure that the brass valve continues to operate efficiently within the system.

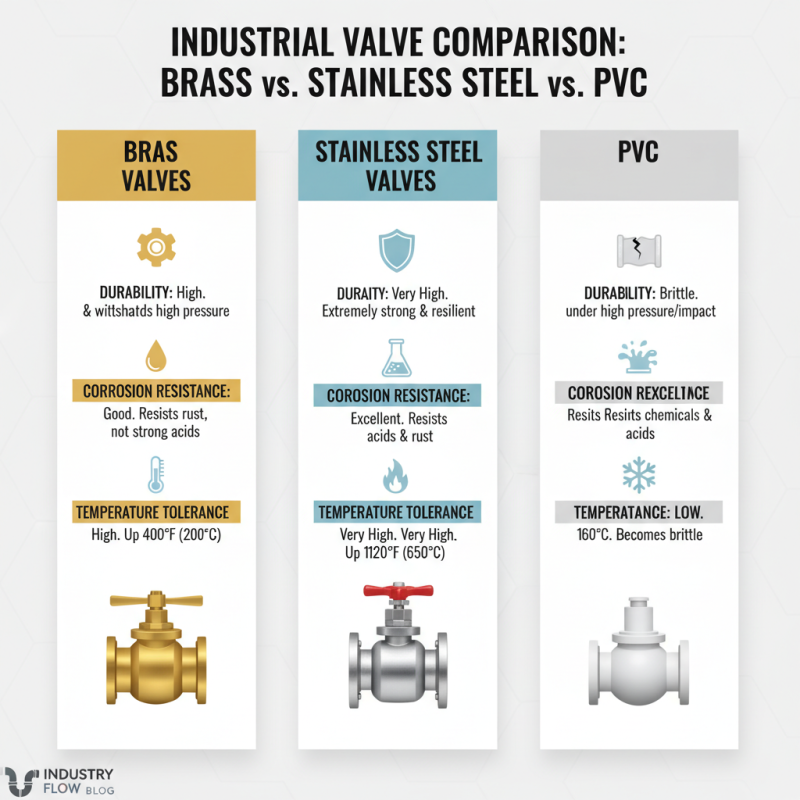

Comparative Analysis: Brass Valves vs. Other Materials

When comparing brass valves to those made from other materials such as stainless steel and PVC, several key factors come into play, including durability, corrosion resistance, and temperature tolerance. Brass valves are known for their robust nature and can withstand high pressures, making them ideal for a wide range of industrial and residential applications. Unlike PVC valves, which may become brittle under high temperatures, brass maintains its integrity and performance even in challenging environments.

Furthermore, the corrosion resistance of brass is noteworthy. While stainless steel offers excellent corrosion protection, it can be more expensive and sometimes less malleable than brass. In contrast, brass provides a good balance between cost-effectiveness and durability, especially in applications where non-potable water flow is involved. This unique characteristic of brass valves allows them to be used effectively in plumbing systems, heating applications, and other settings where reliability is paramount. Ultimately, the choice between brass and other valve materials often hinges on the specific requirements of the application, including environmental conditions and budget considerations.

Related Posts

-

How to Effectively Choose the Right Three Way Valve for Your Industrial Needs

-

7 Unique Benefits of Metal Seated Ball Valves for Global Procurement Success

-

What is a Three Way Valve and How Does It Work in Fluid Systems

-

Understanding the Mechanics and Advantages of 3 Way Ball Valves in Modern Fluid Systems

-

How to Choose the Right Flow Control Valve for Your Applications in 2025

-

What is a Three Way Valve and How Does it Work in Fluid Control Systems