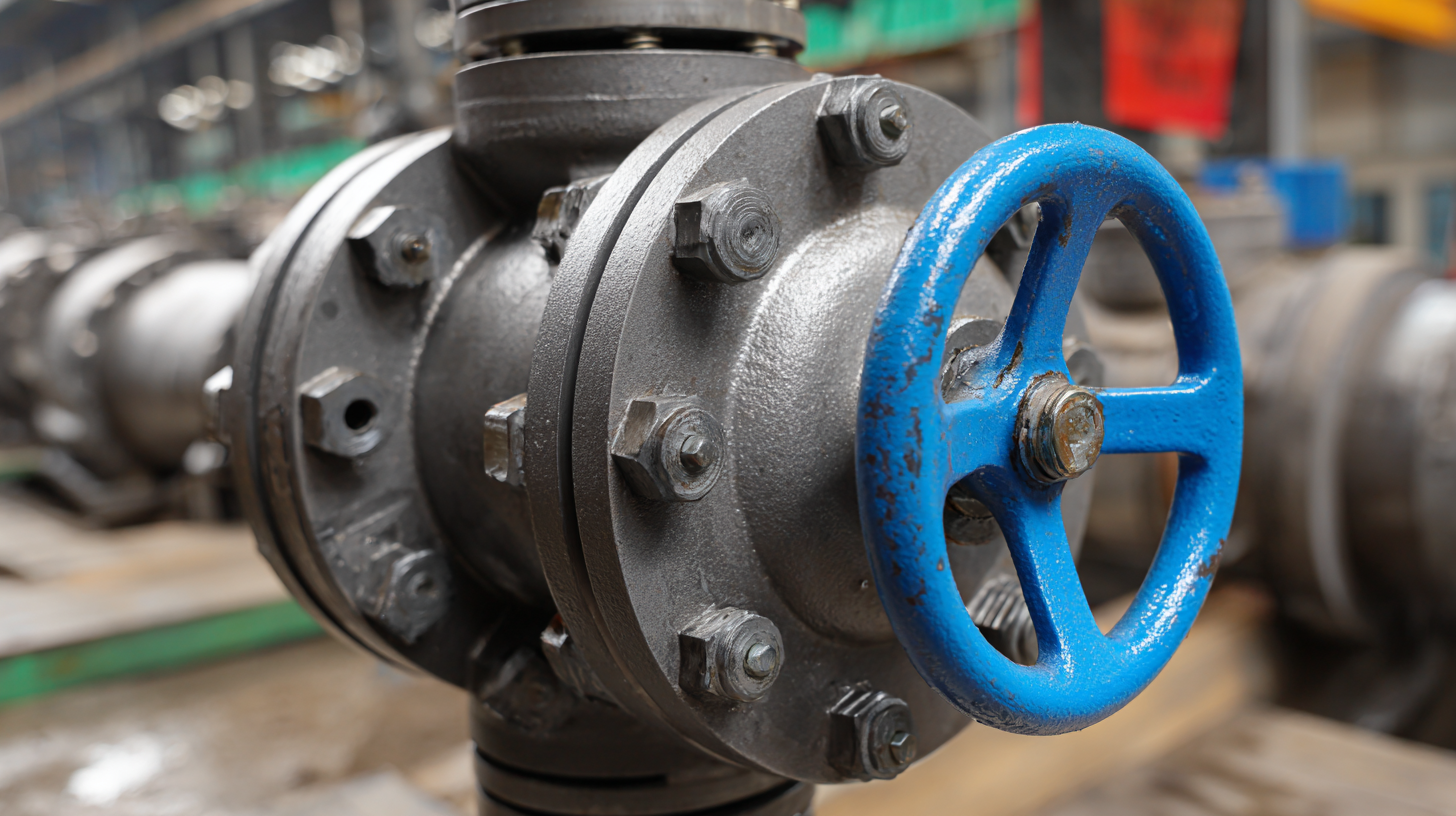

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

In today's fast-paced industrial landscape, selecting the right valve ball valve is critical for ensuring optimal operational efficiency and safety. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 103.2 billion by 2026, with ball valves accounting for a significant segment due to their reliability and versatility in various applications. As industries continue to evolve, the demand for high-quality ball valves sourced from top manufacturers, especially those rooted in China's advanced manufacturing sector, is escalating. These manufacturers are not just meeting local demands but are establishing global trust through rigorous quality standards and innovative design.

This ultimate checklist will guide you through the essential factors to consider when selecting the best valve ball valve for your specific industrial needs, ensuring that you make an informed decision backed by industry expertise.

Advantages of Comprehensive After-Sales Service for Valve Ball Valves

When selecting the best valve ball valve for your industrial applications, it’s essential to consider not just the product itself but also the quality of after-sales service provided. A comprehensive after-sales service can significantly enhance the longevity and efficiency of your valve system. Manufacturers that offer robust support often provide timely assistance in case of malfunctions or maintenance needs, ensuring that your operations run smoothly without unnecessary downtime.

Moreover, a strong after-sales support system includes access to expert technical advice and guidance. This service helps in proper installation and troubleshooting, empowering your team to address minor issues quickly. Additionally, regular maintenance programs offered by manufacturers can extend the lifespan of valve ball valves and optimize their performance. Investing in a supplier that emphasizes after-sales service can be a game changer, ensuring that you receive the necessary support to keep your operations efficient and cost-effective.

Understanding Maintenance Costs Associated with Valve Ball Valves

When selecting a valve ball valve for industrial applications, understanding the maintenance costs is crucial. Maintenance expenses can significantly impact the overall operational budget, making it imperative for businesses to assess the long-term costs associated with various valve types. Regular maintenance ensures that ball valves operate efficiently, reducing the risk of unexpected downtime and costly repairs. Factors such as the quality of materials used, the environment in which the valves operate, and the frequency of use will all play a pivotal role in determining maintenance needs.

Moreover, investing in high-quality valve ball valves may have a higher initial cost but can lead to lower maintenance fees over time. Valves made from durable materials are less likely to suffer corrosion or wear, thus minimizing the frequency of service. It is essential for companies to create a comprehensive maintenance plan that includes routine inspections and timely replacements of worn components. By prioritizing maintenance, businesses can not only enhance the longevity of their valve ball valves but also achieve greater overall efficiency and cost savings in their operations.

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs - Understanding Maintenance Costs Associated with Valve Ball Valves

| Criteria | Description | Estimated Maintenance Cost (Annual) | Frequency of Maintenance |

|---|---|---|---|

| Material | Stainless Steel | $200 | Annually |

| Size | 2 inch | $150 | Semi-Annually |

| Operating Pressure | 150 PSI | $300 | Quarterly |

| Temperature Range | -10 to 100°C | $250 | Yearly |

| Flow Characteristics | Full Port | $100 | Monthly |

Essential Factors in Evaluating After-Sales Support from Manufacturers

When selecting a ball valve for industrial applications, evaluating after-sales support from manufacturers is crucial for ensuring long-term operational efficiency. The nature of industrial environments often demands quick responses to unforeseen issues, making it essential to choose manufacturers who offer comprehensive after-sales service. This includes not only a reliable warranty but also accessibility to technical support, replacement parts, and maintenance services. A strong after-sales support system can significantly reduce downtime and operational costs, allowing businesses to maintain productivity.

Additionally, consider the availability of technical documentation and training resources provided by the manufacturer. Having access to detailed installation manuals and troubleshooting guides can empower your maintenance teams, promoting self-sufficiency while minimizing the reliance on external technicians. Furthermore, some manufacturers offer regular training sessions or workshops, which can enhance your staff's understanding of valve operations and best practices for maintenance.

Ultimately, thorough after-sales support is a critical factor that can influence the overall performance and reliability of your chosen ball valve in an industrial setting.

Comparing Warranty Options and Their Impact on Long-Term Costs

When selecting a valve ball valve for industrial applications, warranties can significantly influence your long-term costs. Investing in a valve with an extensive warranty can often translate to better reliability and fewer maintenance expenses over time. It’s crucial to compare the warranty terms not just on duration but also on what’s covered. Some manufacturers might offer comprehensive coverage that includes parts and labor, while others may only cover parts, leaving you vulnerable to unexpected costs.

Tip: Always inquire about the specific conditions associated with the warranty. For example, check if it’s voided by improper installation or lack of routine maintenance. Understanding these factors can help you avoid future pitfalls.

Another aspect to keep in mind is the manufacturer’s reputation. A reputable company often stands by its products, offering robust warranties that reflect their confidence in quality. This can provide peace of mind as you invest in a valve that will meet your operational demands.

Tip: Research customer reviews and case studies related to warranty claims. They can give you insight into how responsive the company is in honoring their warranties, ensuring your choice is not only about immediate savings but also long-term reliability and performance.

Strategies for Reducing Repair Costs of Valve Ball Valves in Industrial Applications

When it comes to industrial applications, selecting the right valve ball valve is crucial not only for performance but also for cost efficiency. To effectively reduce repair costs associated with valve ball valves, it’s essential to adopt a tailored maintenance strategy. A balanced approach, incorporating reactive, preventive, and predictive maintenance, ensures that valves are not only functioning optimally but are also maintained in a way that mitigates unnecessary repair expenses. Understanding the specific needs of your operation, as well as the operational environment, can guide your maintenance schedule, allowing you to address potential issues before they escalate into costly repairs.

Incorporating advanced technologies, such as HART devices for configuration and calibration, can further enhance the reliability of valve systems. These tools provide detailed communication capabilities, allowing for precise adjustments and monitoring of valve performance. Additionally, investing in high-quality materials, like cryogenic ball valves designed for extreme conditions, can reduce the frequency of repairs over the long term. By implementing these strategies, industrial operations can achieve both efficiency and cost-effectiveness, paving the way for smoother operations and reduced downtime.

Ultimate Checklist for Selecting the Best Valve Ball Valve

This chart illustrates the average costs associated with different aspects of valve ball valves in industrial applications. Understanding these costs can help in making informed decisions regarding the selection and maintenance of valve ball valves, ultimately leading to strategies for reducing repair costs.