Top 10 Tips for Choosing the Best Steel Ball Valve for Your Needs

When it comes to fluid control applications, the selection of the right materials and components is crucial to ensure efficiency and reliability. Among the various types of valves available in the market, the steel ball valve stands out due to its robust construction and excellent sealing capabilities, making it a preferred choice in industries ranging from oil and gas to water treatment. According to a recent industry report by MarketsandMarkets, the global ball valve market is projected to reach USD 12.9 billion by 2025, with a significant portion attributed to the rising demand for steel ball valves in critical applications due to their resilience and durability.

Choosing the best steel ball valve for your specific needs involves understanding various factors such as pressure ratings, temperature control, and material compatibility. Reports indicate that improper valve selection can lead to a staggering 30% inefficiency in systems, prompting the need for effective decision-making. Therefore, it is vital for engineers and procurement specialists to be well-informed about the available options and how they fit into their operational requirements. This guide aims to provide you with the top 10 tips to help you make an informed decision when selecting a steel ball valve, ensuring optimized performance and longevity for your applications.

Understanding the Basics of Steel Ball Valves and Their Applications

Steel ball valves are essential components in a variety of industrial applications, thanks to their simple design and reliable performance. Typically constructed from high-strength materials, these valves consist of a hollow, perforated sphere (the ball) that controls the flow of fluids. According to a report by MarketsandMarkets, the global ball valve market is projected to reach $15.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2%. This growth reflects the increasing demand for efficient fluid control solutions across sectors such as oil and gas, water treatment, and chemical processing.

Understanding the applications of steel ball valves is crucial for making informed decisions. For instance, their ability to provide a tight seal and minimize leakage makes them ideal for high-pressure environments. Furthermore, the valves can operate in extreme temperatures, making them suitable for both cryogenic and high-temperature applications. A recent study published by ResearchAndMarkets highlighted that sectors like power generation and pharmaceuticals are increasingly adopting steel ball valves due to their durability and efficiency, with expected market growth in these industries driving overall performance improvements in fluid management systems. With such a significant role in essential processes, selecting the right steel ball valve tailored to specific needs can optimize overall operational effectiveness.

Key Factors to Consider When Selecting a Steel Ball Valve

When selecting a steel ball valve, there are several key factors to consider to ensure optimal performance and reliability for your specific needs. One major consideration is the valve's material grade. According to industry standards, high-grade stainless steel, such as ASTM A351 CF8M, is often recommended for applications involving corrosive substances due to its superior resistance to oxidation and corrosion. In facilities where the valve will be exposed to harsh conditions, investing in high-quality materials can significantly extend the lifespan of the valve and reduce maintenance costs.

Another critical factor to evaluate is the valve's pressure and temperature ratings. Many applications demand valves that can withstand high pressure and temperature fluctuations. Reports indicate that selecting valves with an adequate pressure rating—typically categorized under ANSI standards—can prevent failures and leaks in systems operating beyond standard conditions. Always consult the technical specifications to find valves that match your operational parameters precisely.

Lastly, consider the size and connection type of the valve. The most commonly used connection types are flanged, threaded, and welded, each providing distinct advantages depending on the system configuration. Proper sizing is essential; a valve that is too large may impede flow, while one that is too small can lead to excessive pressure drops. When making your selection, be sure to analyze flow rates and system requirements to choose a valve that will enhance overall efficiency.

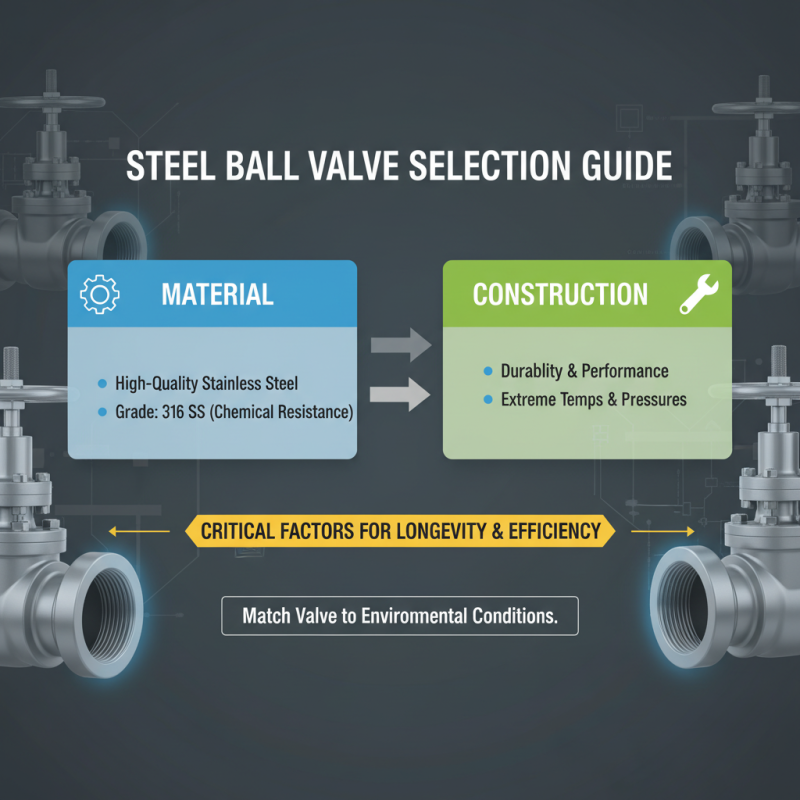

Material and Construction: Ensuring Durability and Performance

When selecting a steel ball valve, the material and construction are critical factors that significantly influence its durability and performance. High-quality stainless steel is often the preferred choice due to its excellent corrosion resistance and ability to withstand extreme temperatures and pressures. The grade of stainless steel also plays a vital role; for instance, 316 stainless steel offers superior protection against chemical exposure compared to lower grades. It is essential to choose a valve that meets the specific environmental conditions of its application to ensure longevity and operational efficiency.

Additionally, the construction of the ball valve should be robust and precise. Look for features like forged bodies and solid construction that enhance strength and reliability. Sealing mechanisms, such as PTFE or graphite packing, can also impact the valve's leak-proof performance and overall functionality. A well-constructed ball valve not only provides reduced friction during operation, leading to smoother flow control but also minimizes the need for frequent repairs or replacements, which can result in significant cost savings over time. By prioritizing the right materials and construction methods, you can ensure that your steel ball valve meets your operational demands effectively.

Assessing Pressure and Temperature Ratings for Your Specific Needs

When selecting a steel ball valve, assessing the pressure and temperature ratings is crucial to ensure it meets your specific operational needs. The pressure rating indicates the maximum pressure that the valve can handle without failing, which is essential for maintaining system integrity. Different industries operate under various pressure conditions, and choosing a valve with an appropriate rating guarantees safety and efficiency in your application. It’s important to account for not only the maximum pressure but also any pressure fluctuations that might occur during operation.

In addition to pressure ratings, temperature ratings should also be carefully evaluated. Steel ball valves are designed to operate within a certain temperature range, and exceeding this range can lead to valve failure or suboptimal performance. Consider the operating environment—high temperatures may cause thermal expansion that affects valve sealing and functionality, while low temperatures can lead to brittleness. By understanding the specific pressure and temperature requirements of your system, you can select a steel ball valve that delivers reliable performance and durability for your particular application.

Top 10 Tips for Choosing the Best Steel Ball Valve for Your Needs

| Tip No. | Tip | Pressure Rating (PSI) | Temperature Rating (°F) | Material |

|---|---|---|---|---|

| 1 | Determine your system's pressure requirements. | 150 | 250 | Stainless Steel |

| 2 | Assess the fluid type and its characteristics. | 300 | 150 | Carbon Steel |

| 3 | Check for compatibility with temperature fluctuations. | 200 | 300 | Bronze |

| 4 | Evaluate the body type (full port vs. standard). | 250 | 200 | PVC |

| 5 | Consider the connection type (threaded, flanged, etc.). | 400 | 100 | Aluminium |

| 6 | Look into the valve size according to pipeline dimensions. | 500 | 300 | Stainless Steel |

| 7 | Assess installation location and space requirements. | 300 | 250 | Cast Iron |

| 8 | Verify the actuator type for proper operation. | 200 | 210 | Stainless Steel |

| 9 | Review maintenance requirements and service life. | 150 | 300 | Bronze |

| 10 | Consider warranty and manufacturer support. | 300 | 400 | Advanced Composite |

Evaluating Manufacturers and Warranty Options for Reliability

When selecting the ideal steel ball valve for your application, it's crucial to evaluate manufacturers thoroughly. Look for companies that have a proven track record of producing high-quality valves. Research their production processes, materials used, and overall reputation in the industry. Engaging with customer reviews and case studies can provide insight into the durability and performance of their products.

Additionally, warranty options can significantly impact your decision. A reliable manufacturer should offer comprehensive warranties that cover defects and ensure long-term functionality. This not only reflects their confidence in their product's quality but also provides peace of mind for your investment.

While evaluating options, consider these tips:

- First, confirm the material compatibility with your specific usage conditions, as this can affect the valve's performance and lifespan.

- Second, assess the valve's size and pressure rating to ensure it meets your operational requirements.

- Finally, do not overlook the importance of after-sales support, as having access to knowledgeable representatives can make a difference in troubleshooting and maintenance.

Related Posts

-

Exploring Market Trends for Steel Ball Valves at the 2025 China Import and Export Fair (Canton Fair)

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Ultimate Checklist for Selecting the Perfect High Pressure 3 Way Ball Valve

-

Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains

-

5 Best Uses of 3 Way Valves in Modern Industries

-

Ultimate Guide to Sourcing the Best Flow Valve Suppliers for Quality Assurance