How to Choose the Right Flow Control Valve for Your Applications in 2025

In the dynamic landscape of industrial applications, selecting the correct flow control valve is crucial for optimizing system performance and efficiency. As we approach 2025, the importance of adapting to technological advancements and industry trends cannot be overstated. Renowned flow control valve expert Dr. Jane Smith emphasizes, "The right flow control valve not only enhances operational efficiency but also plays a significant role in ensuring the safety and reliability of system functions." With various options available, it is essential to understand the unique requirements of each application to make informed decisions.

Choosing the right flow control valve involves considering several factors, including fluid type, pressure, temperature, and flow rate. A comprehensive assessment can lead to improved system functionality and reduced operational costs, significantly impacting the bottom line. As industries continue to evolve, keeping abreast of innovations and regulatory changes will help stakeholders make educated choices regarding their flow control valve needs, ensuring that their systems function optimally in a competitive landscape. Thus, as we look forward to 2025, understanding how to choose the right flow control valve will be paramount for achieving operational excellence.

Understanding Flow Control Valves and Their Importance in Applications

Flow control valves play a crucial role in various industrial applications by regulating the flow of liquids and gases within a system. Understanding their function is essential for optimizing performance and ensuring the safety of equipment. These valves can adjust the width of the passage through which fluids travel, thereby controlling the rate of flow, pressure, and volume within a system. This is particularly important in applications where consistent flow rates are required, such as in hydraulic systems, water treatment facilities, and HVAC systems.

Choosing the right flow control valve involves considering several factors, including the type of fluid, pressure requirements, and specific application conditions. Different industries may have vastly different demands; for example, manufacturing environments may require robust valves that withstand high pressures and temperatures, while more delicate applications, like pharmaceuticals, might need valves that ensure sterile conditions. By understanding the fundamental roles of flow control valves in various applications, engineers can make informed decisions that enhance system efficiency, improve energy savings, and prolong equipment lifespan. The right selection not only optimizes operational processes but also minimizes the risk of system failures and downtime, highlighting the importance of flow control valves in modern industrial infrastructure.

Key Factors to Consider When Selecting Flow Control Valves

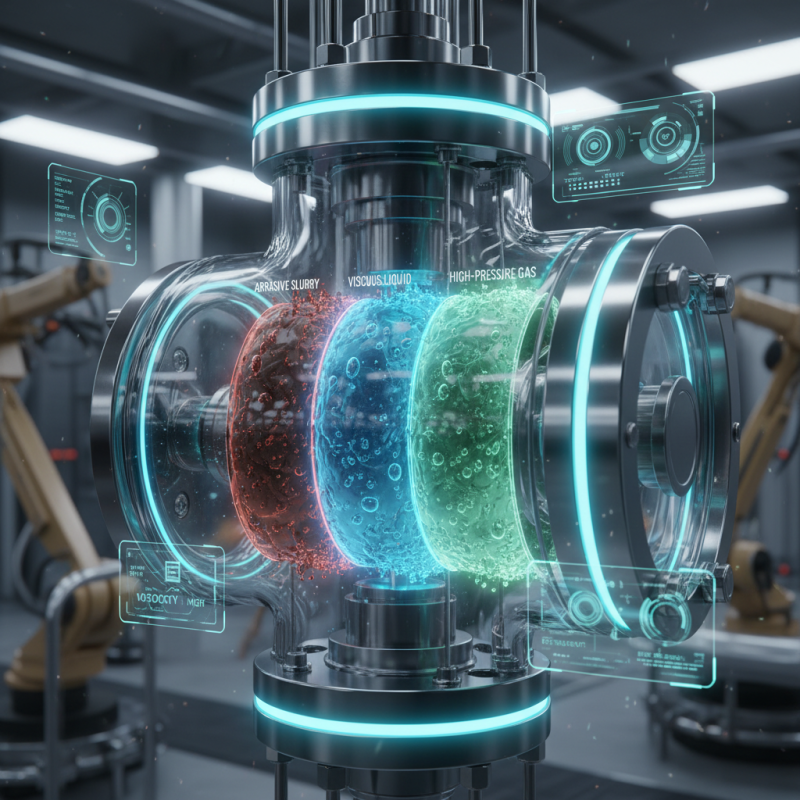

When selecting a flow control valve for your applications in 2025, it’s essential to consider several key factors to ensure optimal performance and efficiency. The first factor is the type of media being controlled. Different fluids—liquids, gases, or slurries—can dramatically impact the choice of valve. For instance, viscous or abrasive substances may require specialized valve designs to avoid wear and tear. Understanding the properties of the media, such as temperature, pressure, and viscosity, is crucial in narrowing down the options.

Another critical aspect to consider is the flow rate requirements. Determining the desired flow rate and pressure drop will help in selecting a valve that can maintain consistent flow under varying operational conditions. For precise applications, a valve with adjustable flow settings or a built-in actuator may provide better control.

Tips: Always consult technical specifications and, if possible, utilize flow simulation software to predict performance outcomes under different scenarios. Additionally, consider the installation space and maintenance requirements, as some valves may necessitate more frequent servicing than others. Prioritizing these factors will lead to a more informed decision, ensuring that the flow control valve chosen will meet application needs effectively.

Types of Flow Control Valves and Their Suitable Applications

When selecting the right flow control valve for specific applications, it's essential to understand the available types and their suitability. Common flow control valves include globe valves, ball valves, and needle valves, each serving unique functions in various settings. Globe valves are ideal for precise flow regulation, making them suitable for applications where fine-tuning of flow is necessary, such as in water treatment and chemical processes. Their design allows for efficient throttling capabilities, which is crucial in systems requiring careful monitoring and control.

Ball valves, known for their durability and quick operation, are frequently used in applications where flow needs to be quickly turned on or off. Their design ensures minimal pressure drop and is often favored in industries like oil and gas, where reliability is paramount. Conversely, needle valves provide significant control over low-flow scenarios, making them perfect for applications in laboratory settings or where fine adjustments are required. Understanding these distinctions aids in making informed decisions, ensuring the selection aligns with operational requirements and enhances system efficiency.

Flow Control Valve Types and Their Applications in 2025

This chart illustrates the suitability of different types of flow control valves for various applications, rated on a scale from 1 to 10. Each valve type serves unique functions in flow regulation, making them preferable in different industrial contexts.

Evaluating Flow Requirements and System Compatibility

Selecting the appropriate flow control valve for your specific applications in 2025 requires a thorough understanding of flow requirements alongside system compatibility. According to the "Fluid Control Market Analysis Report 2023," the global market for flow control devices is expected to reach $8 billion by 2025, reflecting a growing emphasis on optimizing process efficiency and ensuring precise fluid handling. Understanding the specific flow rate and pressure differential required for your application is crucial, as mismatches can lead to inefficiencies or product failures.

Evaluating system compatibility involves more than just assessing the physical dimensions of the valve; one must also consider factors such as valve material compatibility with the fluids being handled, pressure ratings, and the overall design of the system. Industry standards, such as those outlined by the Institute of Electrical and Electronics Engineers (IEEE), emphasize the importance of matching valve characteristics with system specifications to prevent system downtime and reduce maintenance costs.

According to a report from Research and Markets, the demand for smart valve technologies has surged, allowing for enhanced monitoring and real-time data analysis, further underlining the need for compatibility in modern fluid systems to leverage these technological advancements effectively.

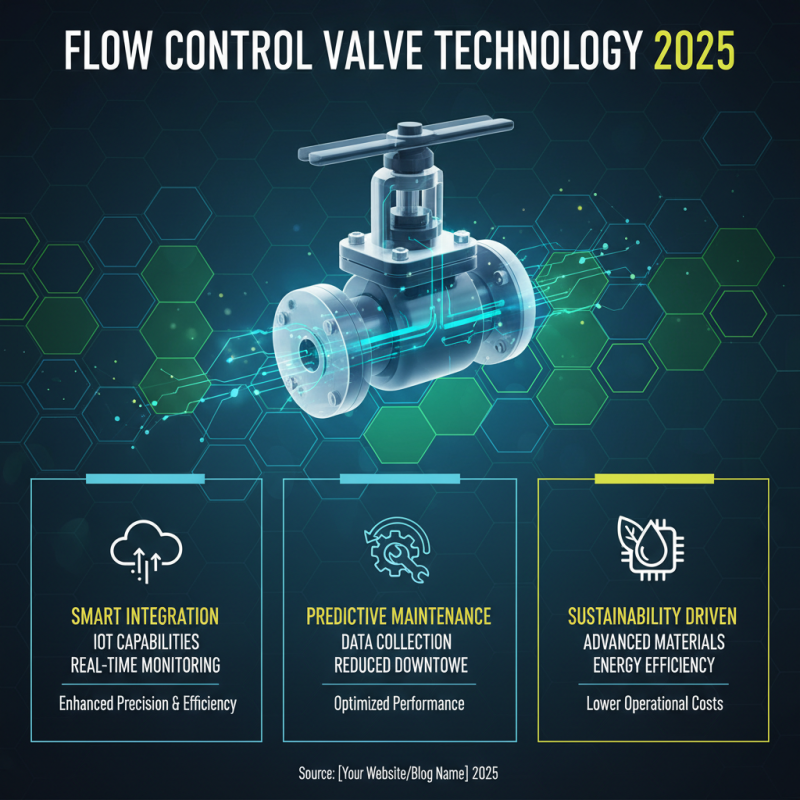

Future Trends in Flow Control Valve Technology for 2025

As we approach 2025, the landscape of flow control valve technology is rapidly evolving, driven by advancements in automation, materials science, and environmental sustainability. One of the prominent trends is the increasing integration of smart technologies, such as IoT (Internet of Things) capabilities, into flow control valves. These smart valves enable real-time monitoring and data collection, allowing for enhanced precision in fluid management and energy efficiency. This shift not only optimizes system performance but also facilitates predictive maintenance, reducing downtime and operational costs.

Another significant trend is the development of environmentally friendly materials and designs in flow control valves. Manufacturers are focusing on creating components that minimize leaks and wastage, compliant with stringent environmental regulations. Innovations, such as advanced sealing technologies and corrosion-resistant materials, are being prioritized to extend the lifespan of valves while promoting sustainable practices. Companies are also investing in research to create lighter, more durable valves that can handle extreme conditions, ensuring reliability and effectiveness across various applications in industries ranging from oil and gas to water management. As these trends continue to shape the market, users seeking flow control solutions will need to stay informed to select the most suitable options for their specific requirements.

Related Posts

-

Ultimate Checklist for Selecting the Perfect Flow Control Valve for Your Systems

-

What is a Ball Valve Ball and How to Choose the Right One

-

Complete Guide to Choosing the Right Full Port Ball Valve for Your Project

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains

-

Advantages of 3 Flanged Ball Valves for Efficient Fluid Control Solutions