How to Choose the Right Pressure Valves for Your Industrial Needs

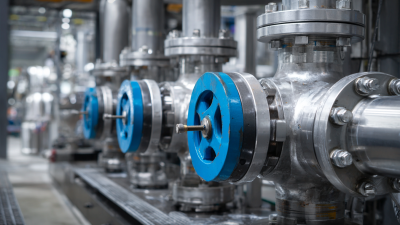

Selecting the appropriate pressure valves for your industrial applications is a critical decision that can significantly impact operational efficiency and safety.

Pressure valves play a vital role in controlling the flow and pressure of fluids within systems, making their selection paramount to ensuring optimal performance and longevity of equipment.

When it comes to choosing pressure valves, various factors must be considered, including the specific requirements of your processes, the types of fluids being handled, and the operating environment.

Additionally, understanding the different types of pressure valves available on the market and their unique features will empower you to make informed choices that meet your operational needs.

This guide aims to provide a comprehensive overview of the essential criteria and best practices for selecting the right pressure valves tailored to your industrial requirements,

ultimately helping you enhance system reliability and safety.

Pressure valves play a vital role in controlling the flow and pressure of fluids within systems, making their selection paramount to ensuring optimal performance and longevity of equipment.

When it comes to choosing pressure valves, various factors must be considered, including the specific requirements of your processes, the types of fluids being handled, and the operating environment.

Additionally, understanding the different types of pressure valves available on the market and their unique features will empower you to make informed choices that meet your operational needs.

This guide aims to provide a comprehensive overview of the essential criteria and best practices for selecting the right pressure valves tailored to your industrial requirements,

ultimately helping you enhance system reliability and safety.

Understanding Different Types of Pressure Valves for Industrial Applications

When selecting pressure valves for industrial applications, it is crucial to understand the various types available and their specific functionalities. Pressure valves can generally be categorized into several types, including safety valves, control valves, and relief valves. Safety valves are designed to prevent system overpressure and protect equipment from potential damage, while control valves regulate fluid flow and pressure within a system. Relief valves are essential for venting excess pressure to maintain the safety and integrity of the system.

In addition to understanding the types, industries, such as food processing and natural gas, have unique requirements for valve technology. For instance, in high-pressure homogenization applications within the food industry, the interaction of particles with valve surfaces can lead to wear and necessitates specially designed valves to ensure quality and operational efficiency. Similarly, as the natural gas sector expands, there's a growing focus on valves that support cleaner energy solutions. Therefore, when choosing the right pressure valves, one must consider the application's specific needs, the operational environment's demands, and the evolving landscape of valve technology which increasingly emphasizes efficiency and sustainability.

Key Factors to Consider When Selecting Pressure Valves

When selecting pressure valves for industrial applications, several key factors must be considered to ensure optimal performance. Firstly, the pressure rating is crucial; it should match or exceed the highest pressure the system will encounter. According to a report by the Global Pressure Relief Valve Market Forecast, the demand for valves that can withstand higher pressures has increased by 15% over the last five years due to advances in industrial processes. This shift emphasizes the importance of assessing the operational conditions and selecting a valve capable of handling those demands.

Another vital consideration is the valve material. The material must be compatible with the fluid it will control, as certain substances can cause corrosion or degradation over time. A recent study published in the Journal of Industrial Valve Research highlighted that improper material selection leads to failure rates of up to 20% in process industry applications. Moreover, factors such as temperature range, fluid viscosity, and potential exposure to harsh chemicals must be evaluated. Ultimately, making informed choices based on these key factors will significantly enhance reliability and efficiency in industrial operations.

Evaluating Performance Standards and Ratings of Pressure Valves

When selecting pressure valves for industrial applications, understanding performance standards and ratings is crucial. Pressure valves are categorized based on their ability to handle specific pressure ranges, temperature conditions, and fluid types, which are often outlined by standardized ratings such as ANSI, ASME, and ASTM. These standards not only define the design and material specifications but also provide guidelines for operational safety and efficiency. By familiarizing yourself with these performance benchmarks, you can ensure that the valve meets your operational requirements and industry regulations.

In addition to basic performance standards, evaluating the valve's rating system, such as the pressure-temperature rating, is essential. This rating indicates the maximum pressure and temperature at which the valve can safely operate. For instance, a valve rated for high pressure and high temperature will be suitable for demanding environments, while those with lower ratings might be suited for less extreme conditions. Thoroughly analyzing these characteristics helps in selecting a valve that minimizes failure risk and maximizes reliability, ultimately leading to smoother industrial operations.

Assessing Compatibility with Fluids and Operating Conditions

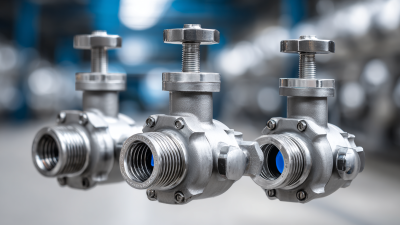

When selecting pressure valves for industrial applications, it's crucial to assess their compatibility with the specific fluids and operating conditions they will encounter. The materials used in valves must be compatible with the fluids, whether they are corrosive, abrasive, or contain particulates. For instance, stainless steel or certain alloys may be required for corrosive chemicals, while other applications might benefit from plastic components that resist certain solvents. Conducting compatibility tests and consulting material compatibility charts can help ensure long-lasting performance and prevent costly failures.

In addition to fluid compatibility, understanding the operating conditions is key to selecting the right pressure valves. Factors such as temperature, pressure range, and flow rates must be considered. Valves need to withstand the maximum pressure and temperature of the system while maintaining functionality. Furthermore, the specific operating environment, such as exposure to extreme temperatures or vibrations, can influence valve durability. Evaluating these parameters helps in choosing valves that not only perform optimally but also ensure safety and efficiency in industrial operations.

Maintenance and Longevity: Choosing Durable Pressure Valves

When selecting pressure valves for industrial applications, durability and maintenance considerations are paramount. Industry reports indicate that approximately 30% of unplanned downtime in manufacturing stems from valve failures, making it crucial to invest in high-quality, robust pressure valves. Materials such as stainless steel or high-grade alloys are often recommended due to their resistance to corrosion and wear, which directly impacts valve lifespan. According to a study by the American Society of Mechanical Engineers (ASME), using durable materials can enhance the longevity of pressure valves by up to 40%, significantly reducing maintenance frequency and costs over time.

Regular maintenance practices also play a critical role in ensuring the longevity of pressure valves. A survey conducted by the Valve Manufacturers Association (VMA) showed that facilities employing scheduled maintenance programs experienced 50% less valve-related failures than those without. Implementing regular inspections, cleaning, and prompt repairs can optimize the operation of these valves while identifying potential issues before they lead to catastrophic failures. In an industry where the cost of downtime can reach thousands of dollars per hour, prioritizing maintenance and selecting the right pressure valves can yield significant financial benefits over the long term.

Related Posts

-

Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

How to Select the Right 3 Flanged Ball Valve for Your Industrial Needs: A Comprehensive Guide

-

Global Leaders Choice for Best Three Way Ball Valves Quality Manufacturing from China

-

How to Effectively Choose the Right Three Way Valve for Your Industrial Needs

-

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications