Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves

In today's industrial landscape, optimal pressure management is crucial for enhancing operational efficiency and ensuring safety across various applications. According to a recent report by MarketsandMarkets, the global pressure control market is projected to reach USD 5.9 billion by 2026, reflecting a growing recognition of the importance of effective pressure management solutions. Pressure valves play a critical role in achieving this goal, as they regulate the flow and maintain the necessary pressure levels in systems ranging from oil and gas to pharmaceuticals. With the increasing complexity of industrial processes, choosing the right pressure valves has become more important than ever. This blog aims to provide a comprehensive checklist to help industries elevate their efficiency by selecting the best pressure valves tailored to their specific needs and applications.

Understanding the Importance of Pressure Management in Industrial Applications

In industrial applications, effective pressure management is crucial for maintaining operational efficiency and safety. Understanding the dynamics of pressure systems enables industries to optimize their processes, reduce the risk of equipment failure, and enhance overall productivity. Pressure management includes monitoring and controlling the pressure within various systems, which directly impacts the performance and reliability of industrial operations.

The use of high-quality pressure valves plays a significant role in achieving optimal pressure management. These valves help regulate the flow and pressure of fluids within a system, ensuring that machinery operates within specified limits. By investing in the best pressure valves, industries can minimize pressure fluctuations, thereby preventing catastrophic failures and costly downtimes. Furthermore, reliable pressure management contributes to energy efficiency, reducing operational costs and supporting sustainability initiatives by lowering waste and energy consumption. The importance of adopting advanced pressure management solutions is clear, as they create a stable environment conducive to innovation and growth in the industrial sector.

Pressure Management Efficiency in Industrial Applications

The chart below illustrates the efficiency of pressure management systems across various industrial sectors. The data showcases how optimal pressure valve performance can significantly enhance operational efficiency and reliability.

Key Features to Look for in High-Quality Pressure Valves

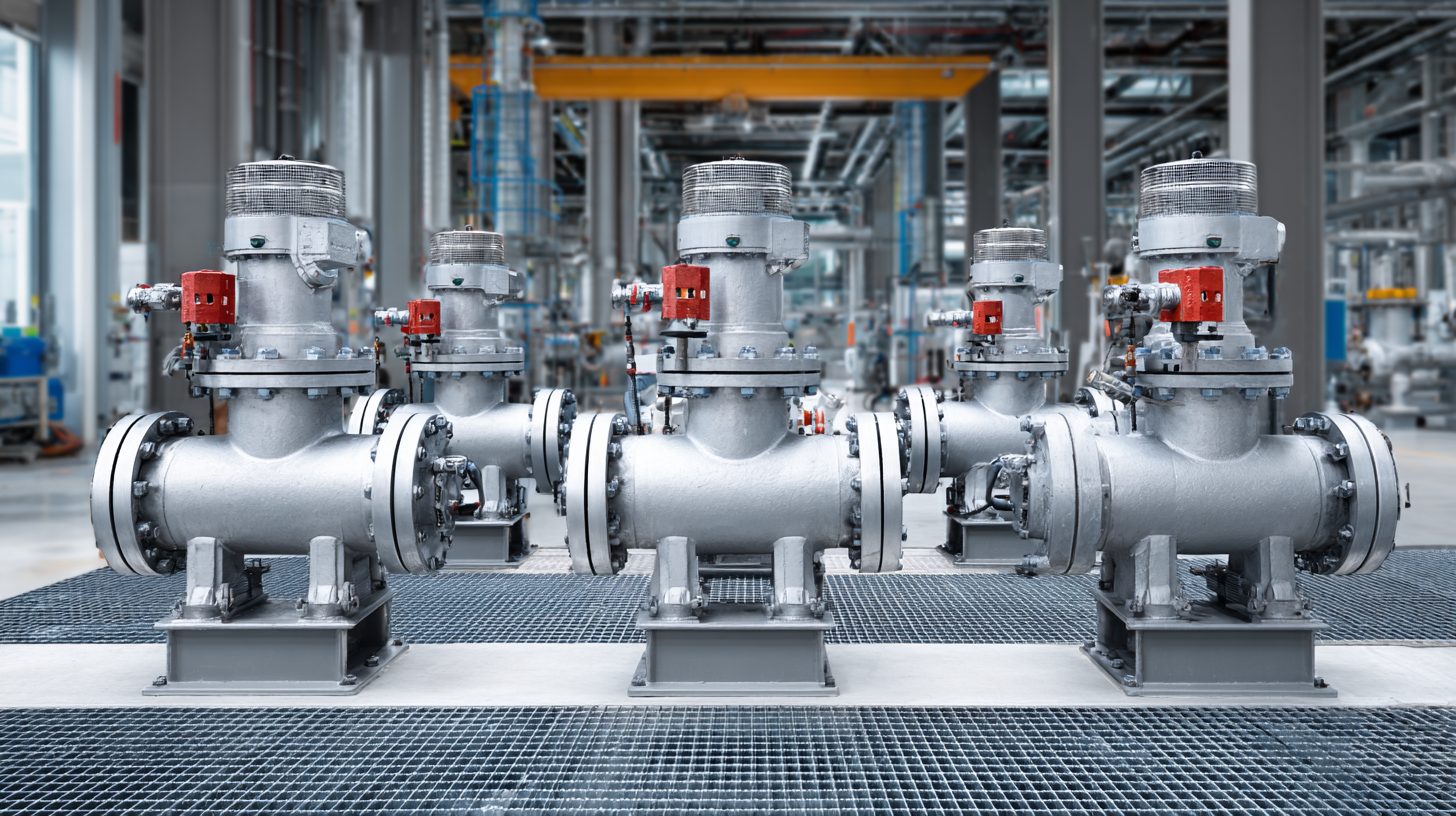

When searching for high-quality pressure valves, it's essential to focus on several key features that directly impact their performance and efficiency. First and foremost, materials matter. Robust materials such as stainless steel or brass not only enhance durability but also ensure resistance to corrosion and wear. This is particularly important in industries that operate under harsh conditions, as the longevity of the valve can significantly affect overall system reliability.

Another critical feature to consider is the valve's design. Look for valves that have a streamlined design for better flow characteristics. This can optimize performance by reducing pressure drops and minimizing energy losses. Additionally, the sealing technology used in a pressure valve plays a pivotal role in preventing leaks and maintaining system integrity. Valves equipped with high-quality sealing mechanisms ensure optimal performance, even in fluctuating pressure scenarios.

Moreover, the adjustability and control capabilities of the valves cannot be overlooked. High-quality pressure valves should allow for precise adjustments to meet specific operational needs. Valves with integrated automation can further enhance efficiency by providing real-time monitoring and control of pressure levels. By focusing on these key features, industries can ensure they invest in pressure valves that not only meet their current requirements but also adapt to future challenges seamlessly.

Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves

| Feature | Description | Importance |

|---|---|---|

| Material Quality | High-grade materials ensure durability and resistance to corrosion. | Reduces maintenance costs and extends valve lifespan. |

| Pressure Range | Ability to handle varying pressure levels without failure. | Essential for applications with fluctuating systems. |

| Response Time | Speed at which the valve reacts to pressure changes. | Crucial for maintaining system stability and safety. |

| Flow Coefficient (Cv) | Measure of the valve's ability to pass fluid. | Impacts flow rate and energy efficiency in the system. |

| Size and Configuration | Available sizes and layout options for installation. | Ensures compatibility with existing piping systems. |

| Maintenance Requirements | Frequency and complexity of required maintenance tasks. | Influences operational efficiency and downtime. |

Types of Pressure Valves: Choosing the Right Fit for Your System

When it comes to managing pressure in industrial systems, selecting the right type of pressure valve is crucial. Pressure valves come in various types, including relief valves, control valves, and safety valves, each serving specific functions within a system. According to a recent report by the International Society of Automation (ISA), improper valve selection can lead to inefficiencies, contributing to up to a 20% increase in operational costs. Understanding the unique characteristics and applications of each valve type can significantly enhance system performance and reliability.

For example, relief valves are designed to prevent system overload by releasing excess pressure, while control valves modulate flow to maintain desired pressure levels. Safety valves serve as a fail-safe in case of overpressure incidents. Industries must evaluate their operational needs and choose valves based on parameters such as flow rate, pressure range, and media type to ensure optimal function.

Tip: Always consult manufacturer's guidelines and specifications to ensure acquisition of the right valve type for your specific application. Moreover, consider integrating advanced monitoring solutions to track valve performance continuously. This proactive approach can help in identifying potential issues before they escalate, thereby enhancing overall efficiency.

Maintaining Efficiency: Best Practices for Pressure Valve Operation

Effective operation of pressure valves is crucial for maintaining efficiency and safety in various industrial applications. To achieve optimal performance, operators should first prioritize regular maintenance schedules. Routine inspections for wear and tear can prevent unexpected failures and extend the lifespan of the valves. Implementing a proactive maintenance plan, including timely replacements of seals and gaskets, ensures that the pressure management systems operate smoothly under specified conditions.

Effective operation of pressure valves is crucial for maintaining efficiency and safety in various industrial applications. To achieve optimal performance, operators should first prioritize regular maintenance schedules. Routine inspections for wear and tear can prevent unexpected failures and extend the lifespan of the valves. Implementing a proactive maintenance plan, including timely replacements of seals and gaskets, ensures that the pressure management systems operate smoothly under specified conditions.

Another key practice is to monitor and adjust the pressure settings regularly. Variations in system demands may require recalibrating valves to maintain ideal pressure levels. Utilizing advanced monitoring tools can provide real-time data on performance, helping operators make informed adjustments. Additionally, training personnel on the proper handling and operation of pressure valves can significantly reduce the risk of human error and enhance overall system efficiency. By fostering a culture of continuous improvement and vigilance, facilities can optimize their pressure management systems significantly.

Future Trends in Pressure Valve Technology for Enhanced Performance

The future of pressure valve technology is being shaped by significant advancements aimed at enhancing efficiency and performance, particularly in critical applications like hydrogen fueling stations. With the global HPLC check valve and ball valve seating market projected to grow from $21.27 million in 2024 to $34.93 million by 2032, at a CAGR of 6.39%, the demand for precise pressure management solutions is evident. These valves are essential components in ensuring the safe and efficient operation of various systems, including those used for hydrogen compression.

Moreover, breakthroughs in compressor technology for hydrogen fueling stations are setting the stage for a transformative shift in the energy landscape. Hydrogen, recognized for its abundant, clean, and carbon-free properties, is increasingly seen as the key to achieving deep decarbonization in the transportation sector. As the market for fuel cell vehicles expands, the need for a robust hydrogen refueling infrastructure becomes paramount. Innovations in pressure management technologies, particularly in the valve sector, are crucial not only for maintaining optimal operational conditions but also for supporting the growth of a sustainable energy future.