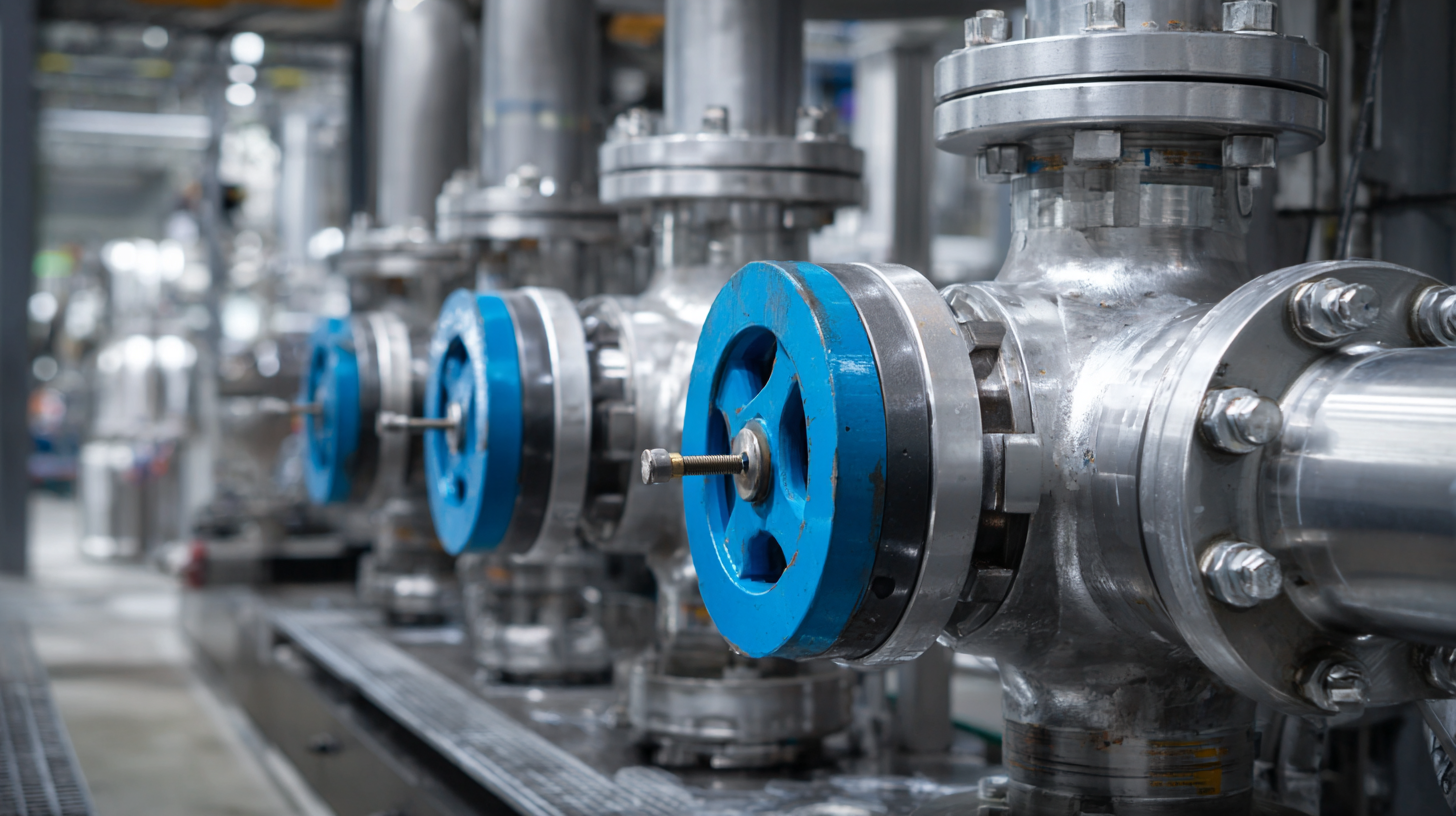

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

In the realm of industrial applications, the significance of a high pressure ball valve cannot be overstated. According to a recent report by Markets and Markets, the global valve market is projected to reach USD 79.9 billion by 2025, with high pressure ball valves playing a crucial role due to their superior performance in managing the flow of fluids under high-pressure conditions.

These valves are essential in industries such as oil and gas, chemical processing, and power generation, where maintaining safety and efficiency is paramount. The reliability and durability of high pressure ball valves are vital for preventing leaks and ensuring operational integrity, making them a preferred choice among engineers and industry professionals.

As industries continue to evolve, understanding the applications and benefits of high pressure ball valves will be integral to optimizing performance and enhancing productivity across various sectors.

The Evolution of High Pressure Ball Valve Technology in 2025

The evolution of high pressure ball valve technology in 2025 reflects significant advancements that enhance performance and reliability in industrial applications. As industries face increasing demands for efficiency and safety, manufacturers have prioritized the development of ball valves that can withstand extreme pressures and temperatures. This evolution is characterized by the introduction of innovative materials and design methodologies that improve durability while reducing maintenance needs. For instance, the use of advanced composites and coatings has made these valves more resistant to corrosion and wear, thus extending their operational lifespan.

The evolution of high pressure ball valve technology in 2025 reflects significant advancements that enhance performance and reliability in industrial applications. As industries face increasing demands for efficiency and safety, manufacturers have prioritized the development of ball valves that can withstand extreme pressures and temperatures. This evolution is characterized by the introduction of innovative materials and design methodologies that improve durability while reducing maintenance needs. For instance, the use of advanced composites and coatings has made these valves more resistant to corrosion and wear, thus extending their operational lifespan.

Moreover, the integration of smart technology into high pressure ball valves has revolutionized their usability. In 2025, we see a trend towards incorporating IoT capabilities, allowing for real-time monitoring and control of valve operations. This connectivity enables predictive maintenance, reducing downtime and operational costs while increasing overall system efficiency. Ultimately, the ongoing advancements in high pressure ball valve technology not only enhance industrial processes but also contribute to sustainability by optimizing resource usage and minimizing waste. The future looks promising as industries adapt to these innovations, leading to safer and more efficient operations.

Key Benefits of High Pressure Ball Valves in Industrial Settings

High pressure ball valves play a critical role in various industrial applications due to their unique design and functionality. One of the key benefits of these valves is their exceptional sealing capability at high pressures. This ensures that even in demanding environments, such as oil and gas or chemical processing, the risk of leaks and spills is significantly minimized. The tight seal offered by high pressure ball valves safeguards not only the integrity of the system but also enhances operational safety, making them essential for minimizing environmental impact.

Another significant advantage is their ease of operation and reliability. High pressure ball valves can be actuated swiftly, allowing for quick isolation of sections in a piping system when needed. This responsiveness is crucial in industries requiring rapid response to changing conditions, thereby optimizing workflow and maintenance procedures. Additionally, their robust construction ensures longevity, reducing the need for frequent replacements, and ultimately lowering operational costs for industrial plants. The combination of safety, efficiency, and durability makes high pressure ball valves an indispensable component in many industrial settings.

Emerging Trends in Ball Valve Materials and Designs for Enhanced Performance

Emerging trends in ball valve materials and designs

indicate a significant evolution aimed at enhancing performance and meeting the rigorous demands of industrial applications. Recent studies show that advanced materials such as duplex stainless steel and

PEEK (Polyether ether ketone) are gaining popularity due to their superior corrosion resistance and mechanical properties. According to a report by MarketsandMarkets, the global ball valve materials market is projected to grow from $4.1 billion in 2022 to

$6.3 billion by 2027, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is driven by the need for

durability and reliability in high-pressure environments where traditional materials may fail.

In addition to enhanced materials, innovative designs are revolutionizing ball valve functionality. Low-torque designs and optimized flow paths are becoming prevalent, enabling faster and more efficient operation in industrial settings.

Research indicates that the integration of smart technology, like IoT sensors for real-time performance monitoring, is expected to streamline operations and reduce downtime, aligning with the increasing trend toward automation in industrial processes.

A report from ResearchAndMarkets highlights that the smart valve market is anticipated to reach $2 billion by 2026, underlining the importance of these advancements in maintaining competitive advantage within the industry.

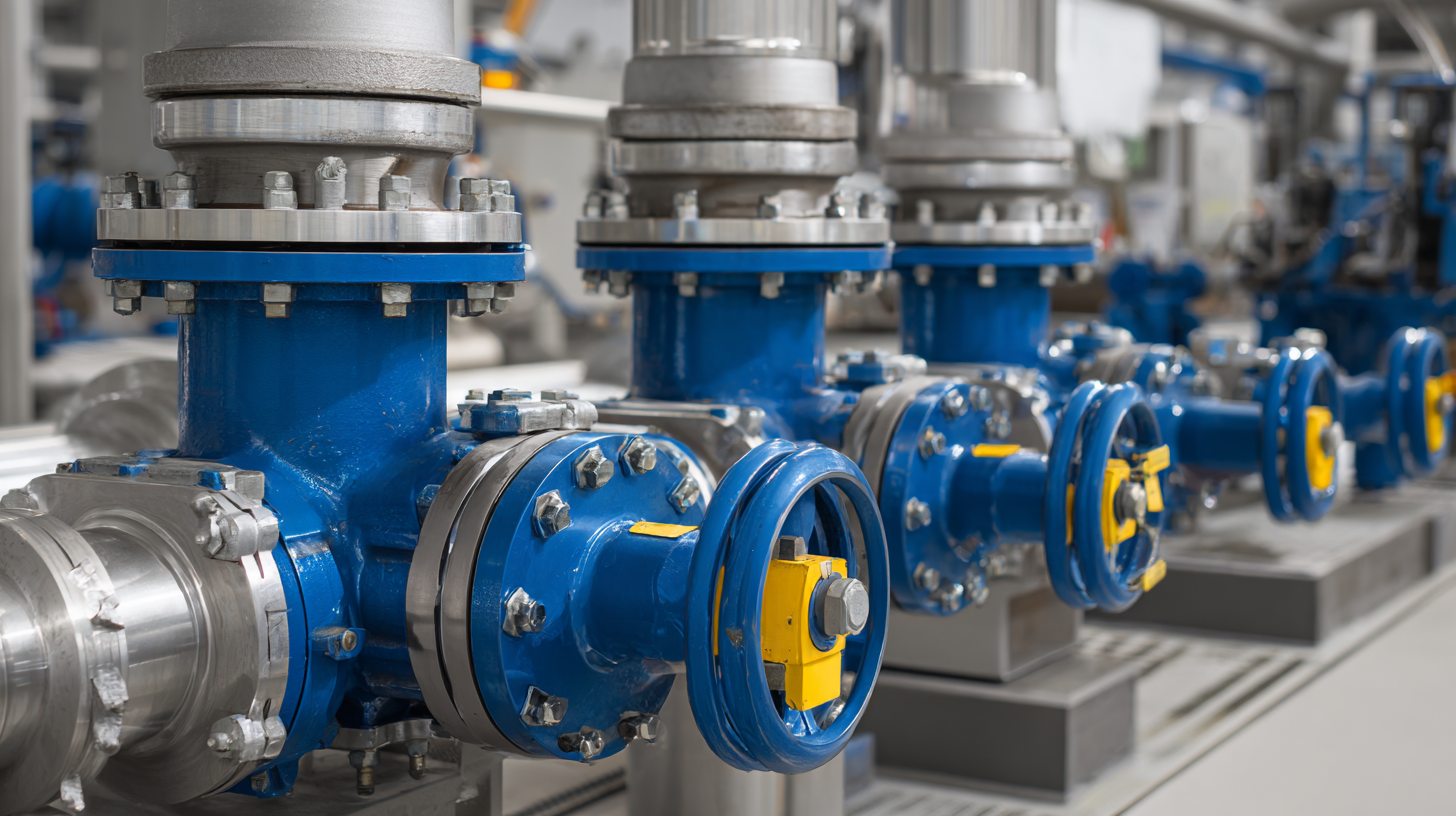

Comparative Analysis: High Pressure Ball Valves vs. Traditional Valve Systems

High pressure ball valves have become essential in industrial applications due to their superior performance compared to traditional valve systems. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 21.93 billion by 2027, driven largely by the increasing demand for efficient and reliable fluid control systems. High pressure ball valves, in particular, offer advantages such as minimal flow resistance and a lower risk of leakage, which is crucial in sectors like oil and gas, where even minor leaks can lead to significant financial and environmental repercussions.

When comparing high pressure ball valves with traditional valve systems, it’s critical to focus on their operational efficiency and durability. Data from the American Society of Mechanical Engineers (ASME) indicates that ball valves can operate at higher pressures and temperatures than their gate and globe valve counterparts, with a typical pressure rating of up to 10,000 psi. This capability not only enhances the safety and reliability of industrial processes but also results in lower maintenance costs over time due to their robust design. As industries continue to prioritize operational efficiency and safety, the transition to high pressure ball valves over traditional systems is becoming increasingly evident.

Future Innovations: Smart Ball Valve Technologies and Their Impact on Industry

The evolution of smart technologies is revolutionizing many sectors, and industrial applications are no exception. Smart ball valve technologies are at the forefront of this transformation, offering unprecedented control and efficiency in fluid management systems. These advanced valves are equipped with sensors and IoT capabilities, allowing for real-time monitoring and automation. As a result, industries can achieve higher precision in regulating flow rates, reduce wastage, and enhance safety protocols in high-pressure environments.

One of the most significant impacts of these innovations is the ability to predict maintenance needs through data analysis. By utilizing predictive analytics, companies can minimize downtime and extend the lifespan of their equipment. Furthermore, smart ball valves can be integrated with existing systems, enabling seamless communication and data exchange. This not only streamlines operations but also facilitates compliance with regulatory standards, making it easier for companies to adapt to changing environmental and safety guidelines. As industries continue to embrace these technological advancements, the future promises more efficient and sustainable practices that could redefine operational benchmarks across various sectors.

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

This chart illustrates the adoption rates of various types of ball valves in industrial applications, highlighting the growing significance of smart ball valves and their innovative features, which enhance operational efficiency and safety.